|

|

|||||||

| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Steel Baron Quality?

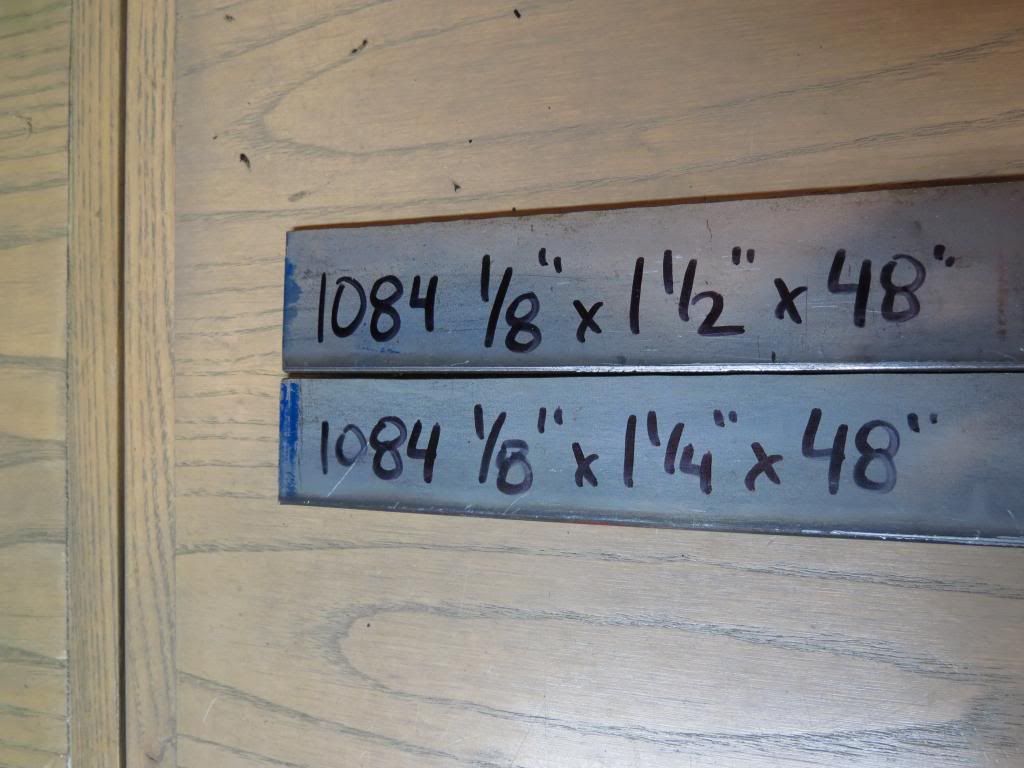

I just received my first order from the Steel Baron 1084

4' of 1/8 x 1.25 & 4' of 1/8 X 1.5 I am questioning the quality of the material, as this is my first order. The steel is not flat, it is bent and twisted. Also is it not cut to the correct width, the 1.25 is 1.33 to 1.37, the 1.5 is 1.47 to 1.53. The edge cut is so crappy it looks like something I did free hand with a band saw. Is this what they sell for quality? Thanks Last edited by Ruebarb; 11-20-2012 at 10:45 AM. |

|

#2

|

|||

|

|||

|

I've never had any such problems ordering from Aldo. Everything that I've ordered was spot one and cut evenly. I think you owe it to Aldo to address this problem with him and give him a chance to make it right.

Doug __________________ If you're not making mistakes then you're not trying hard enough |

|

#3

|

|||

|

|||

|

Quote:

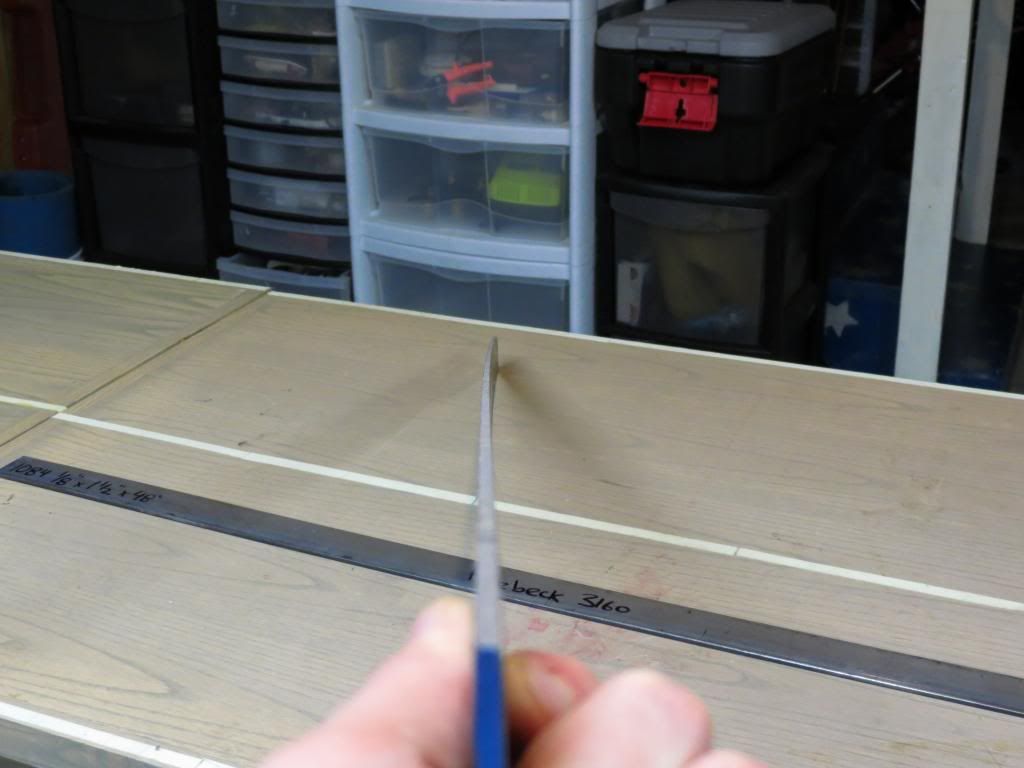

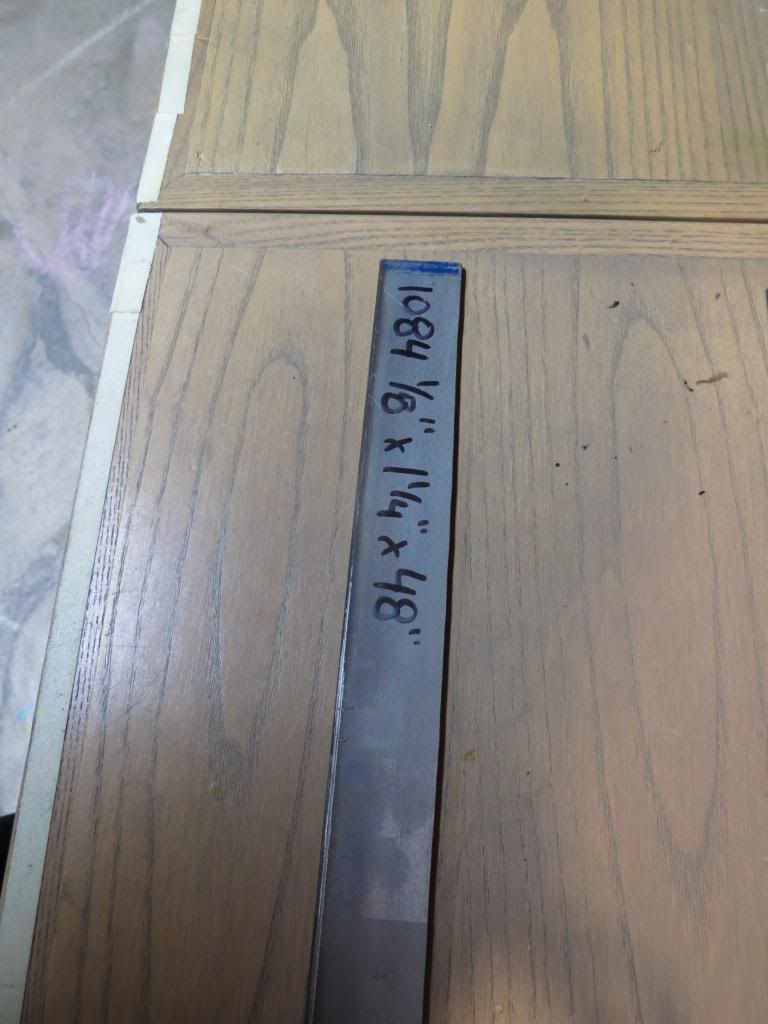

I just want to ensure that I am not being over critical, I was expecting mill quality squared steel and cuts, and to be flat. A simple rectangle bar of steel. I don't want to wrongly accuse a vendor. Here are some pics Bent & twist  Not touching flat surface  Wavy Edge - zoom in, even the shadow is wavy, not an illusion  Notice the wavy gap when compared to the mill edge  1.25" width?

|

|

#4

|

||||

|

||||

|

Now the steel being twisted I would have a problem with but the widths being off and the curvature are pretty common.

If you had ordered precision ground tool steel and had these problems then it would be a major complaint but with as-rolled carbon steels, some warpage, and variance in width from shearing/cutting are to be expected. I've had it from every vendor I've tried over the years (Aldo, Jantz, Trugrit, Admiral, etc). Sometimes to a greater extent, sometimes to a lessor. Its just one of those tradeoffs for paying 1/3 the price of precision ground tool steel. |

|

#5

|

||||

|

||||

|

I would have to assume your not forging.

Definitely give Aldo a call and voice your concerns, his CS is top notch , and he will make you happy. __________________ American Bladesmiths Society Apprentice Smith Work Smarter Not Harder www.OliverKnives.com |

|

#6

|

|||

|

|||

|

His steel is fantastic and honestly, to me warped steel is just part of the game. It doesn't take much to straighten it out.

|

|

#7

|

||||

|

||||

|

I've dealt with Aldo for a LONG time, and without a doubt, when I want QUALITY steel, that's where I go. Now, to qualify that statement, "Quality" means the chemistry.... Aldo has always had the steel chemistry he sells checked by at least two different sources before he offers it for sale.

It is common for Aldo's steel to be slightly oversize....to me that is a "value added" aspect.....he's actually giving you more then what you asked for/ordered. Now, to the flatness/twisted...... that's a different story. Slight bowing can be expected out of "Mill Run" steel.....the twist however, is something else. It might have occurred in shipping, but I would suggest calling Aldo about it. As Dwane mentioned....for a forger it's no big deal. If you're a stock removal maker, and want absolutely clean, flat, and true stock, your going to have to pay the extra money for "precision ground" stock. __________________ WWW.CAFFREYKNIVES.NET  Caffreyknives@gmail.com "Every CHOICE has a CONSEQUENCE, and all your CONSEQUENCES are a result of your CHOICES." |

|

#8

|

|||

|

|||

|

Thanks all for the comments.

I plan on cutting a knife from the stock and then heat treating this myself, this is all first time for me. I also didn?t mention, as I saw it this morning that the bars are also bowed along the width plane (looking like a smile laying flat), not the thickness plane like a leave spring. I am hearing that a rough cut edge and bowing on the thickness plane are normal for his steel and other carbon steels in general? As it is not precision ground. I don't see anything on his website about precision ground steel 1084 or 0-1 Tool steel, so I am guessing I would need another vendor for such? This is all new to me, I figured just cutting out a blade would be the hard part, not finding flat and straight stock Last edited by Ruebarb; 11-17-2012 at 07:38 AM. |

|

#9

|

||||

|

||||

|

I haven't purchased from Aldo yet but have been able to find a good selection of precision ground steels at Jantz. They cost a little more but well worth it in my opinion. I just received a bar of precision ground CPM154 from them and it looks great.

I don't think they carry 1084 but they do have precision ground 0-1 Tool Steel. __________________ Stay away from fast women and slow horses |

|

#10

|

||||

|

||||

|

Can't comment on the Steel Baron since I have yet to used him, but I did just receive an order from Admiral and I am very satisfied with it. I have not tried Steel Baron yet. I wanted O-1 for forging, and the 1/4"x1.5"x36" piece I received was beautiful. Almost too beautiful to put a hammer to it. Alas, I missed the fine print and ordered a precision ground piece! The 5/32"x1.5"x72" piece of ATS-34 is also a straight well sheared piece, but not precision ground! Packed nicely in a heavy duty tube with steel end caps screwed on. But don't be in a hurry, even though Admiral is only 300 miles away from me it took calender 8 days cheapest method. But I figured that.

I would definitely call the owner Aldo and let him know. But, it might be just easier to use than re-pack and send back and wait again. I have heard great things about Kelly Cupple's steel for forgers (no SS). I will order from him next. His prices are very good, and his shipping is a bit cheaper. But the man has a great website for a bladesmith from forge parts, refractory cement, Inswool, ceramic platens, etc. http://www.hightemptools.com/steel.html Please post what the outcome of this was. Thanks. Tony Z |

|

#11

|

||||

|

||||

|

Quote:

Tony Z |

|

#12

|

|||

|

|||

|

Thanks All, I'll check out some of the others listed too for precision ground.

I spoke to Aldo, I live in Mass and happened to be going back to NJ for Business, so I'll be dropping by tomorrow at his shop in Hawthorn. He said the steel should have been flat and straight, it must have missed the straightener. He is going to replace the stuff, he seams like a real nice guy. Thanks for the info, I didn't want to ask someone to replace something that wasn't warrented to need replacing. |

|

#13

|

|||

|

|||

|

I wish I had seen the pictures before I had made my comment. I think your description was a little over blown. I can see where a uniform thickness is a major thing in stock removal and flatness is a close second. For that you will have to pay extra or buy a surface grinder and straighten the steel yourself. Straightening annealed steel in not difficult. The variation in width is really minor and is far removed from being cut free hand with a band saw. Anyway, I would recommend that you lay out the blade at least slightly inside the edge of the bar and not use it's edge as a straight line. Except for when you want a dead straight spine or edge, it seems not to work out well. It looks like's it harder to bring the curves into the straight line of the edge for some reason. At least that's what I've seen in the work in progress photos of some stock removal knives incorporating the edge of the bar into the blade.

Even if you start out with a flat piece of steel and you do strictly stock removal, you will eventually have a situation where a blade will warp on you and you will have to learn how to straighten it. Doug __________________ If you're not making mistakes then you're not trying hard enough |

|

#14

|

|||

|

|||

|

Quote:

I agree I should learn how to handle bent blades, but I need start with the simple first before attempting more complex. I could address bent/bowing along the length like a leaf spring, but I have no way of bending it width wise. I appreciate your help. |

|

#15

|

||||

|

||||

|

Btw these pics are a good example of what can happen during heat treat if there is stress in the steel. The steel mill rolling out steel, the steel distributor shearing steel, the straightening machine straightening, it, etc can all put stress in the steel.

If you straighten the piece cold, when you go to heat treat it it will probably try to warp back into its previous shape (or another shape). What you need to do is "normalize" the blade to relieve the stresses. It will really cut down on warping issues during heat treatment. You can correct curvature by bending it when the steels hot during normalizing. I've even had steel warp on me when grinding the blade. Since I started normalizing everything, instead of just forged blades, it made my life easier. If you want to skip the issues with as-rolled steel you can get the precision ground. I rarely use it but I used to get mine from www.flat-stock.com . At the time they had the best prices. You'll pay a lot more than the rolled steel but it will come accurately machined (they usually list the tolerances). I don't think I've ever come across the 10xx series in precision ground, but you can get O1, A2, etc....which need a more indepth heat treatment. |

|

| Tags |

| angle, ats-34, back, bee, blade, common, edge, flat, for sale, forge, forging, hammer, hand, horn, knife, knifemaking, knives, make, man, material, notch, post, simple, steel, stock removal |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| New Jersey Steel Baron & Niagara Specialty Metals | Matthew Gregory | Knife Making Discussions | 3 | 05-28-2010 10:57 PM |

| Winner Jonathan Baron! | KNAdmin | Knife Photography Discussion | 6 | 08-29-2004 01:17 PM |

| Week 53 - Jonathan Baron | jbaron | Knife Photography Discussion | 0 | 08-06-2004 02:57 PM |

| Jonathan Baron | Raymond Richard | The Outpost | 2 | 01-02-2004 07:39 PM |

| Custom Baron | Johnny Stout | The Display Case | 1 | 06-28-2002 11:24 AM |