|

|

|||||||

| Register | All Photos | FAQ | Members List | Calendar | ShopStream (Radio/TV) | Search | Today's Posts | Mark Forums Read |

| The Damascus Forum The art and study of Damascus steel making. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

1st attempt a Mosaic Pattern

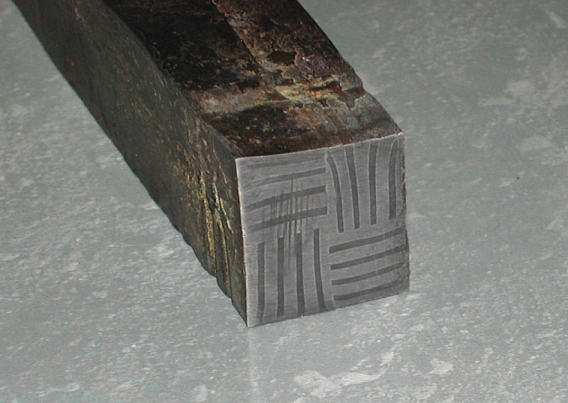

As the subject says, this is my first attempt at a mosaic pattern damascus. What follows is the first work in progress photo of the completed welded bar. This is all being done with my "Arm Strong powered" hammer. So I wanted to pick a simple pattern that could be done with just layerd bars.

The material is 1084 and 15N20. I will next be doing an acordian cut at my bandsaw. With luck my welds are as good in the middle of the bar as they are on the ends (I cut both ends clean to check). I course polished and lightly etched one end to see my pattern. If all turns out well I'll post more photos in this thread later on. __________________ Scott B. Jaqua http://www.hagersonforge.com http://hagerson.livejournal.com ---------------------------------------------------------------------------------------------- The most important right of all, is that of Free Speech. With out that, all your other rights will soon be taken away. So, I may disagree with what you say, but I will defend until death, your right to say it! |

|

#2

|

|||

|

|||

|

Cool, Scott! It's looking good!

Knowing you did that by hand makes me glad I have a press!

|

|

#3

|

||||

|

||||

|

Wonderful! Once you get that billet opened up and into a blade you might as well give up.....once your there the sickness is incurable!

You'll be waking up at night thinking of cool new patterns to build........and wishing you had a notebook by the bed so you don't forget. You'll be waking up at night thinking of cool new patterns to build........and wishing you had a notebook by the bed so you don't forget.  Make sure you post some pics of the blade(s) that come out of that beauty! __________________ WWW.CAFFREYKNIVES.NET  Caffreyknives@gmail.com "Every CHOICE has a CONSEQUENCE, and all your CONSEQUENCES are a result of your CHOICES." |

|

#4

|

||||

|

||||

|

Way cool work!

Man That makes a guy glad to have a press or want one real bad in you case I bet. But really nice work. But now for a question. What would happen if you twisted it then forged it flat? Or twisted it then forged into a square bar and then acordian cut then bar? Just wondering as I am working up a similar bar but with more layers. Any and all answers would be great.

__________________ Kevin W Vogl |

|

#5

|

||||

|

||||

|

Well, no joy last night..............

I got back into the shop to do the accordian cut and flatten the bar out. I did some clean-up grinding on the sides of my bar first to check my welds for any gaps and everything looked good. I then cut my bar and inside the cuts all looked good. But when I went to flatten my bar, two of the three welds to assemble the bar failed. In assembling my bar, I first surfaced and welded two pairs of two of the small bars to each other. I then surfaced and welded the pairs togather. It was this last weld and one of the first welds that failed. None of my welds in the laminated bars failed at all. So I think I need to adjust my technigue when welding the larger bars. Which isn't too much of a surprise. I had to improve my technigue when I made the jump from welded cable to layered billets. Most likely, I need to do more then mearly double the soak time in the forge like I did. I don't think I need to hit harder while setting the weld. But maybe I need to hit harder on the follow-up welding course. The welds where clearly set, with no gaps or inclussions. I think I just didn't get complete fussion. Overall I'm not mad, just disapointed (which for those that know me well is a major deal, I had to get my temper under control or die a few years back, bladesmithing is one of the tools to keep my blood pressure in check). It's about 6 hours down the drain, all total. As for wanting a press. It might help my welds, but I don't see it speeding me up any. Most the the time was in preparing the bars at each stage, for the next, the band saw and grinder work. In any case I'll try it again some time soon. I figure it's got to be something small that I'm doing wrong. Otherwise I would not have gotten as far into the project as I did. I know this can be done with a hammer  Oh! one thing I did learn.... I used a Sharpi pen to layout my accordian cuts. In the past when laying-out ladder patterns I had found the heat, oil and water caused my lines to wash away. While I can fake it on a ladder pattern. I figured I didn't want to try that on the accordian cut. So I tried protecting the pen lins with clear artists matte spray. It worked like a champ! Nice clean clear dark layout lines during the entire cutting process. So at least I learned something (shrug!) __________________ Scott B. Jaqua http://www.hagersonforge.com http://hagerson.livejournal.com ---------------------------------------------------------------------------------------------- The most important right of all, is that of Free Speech. With out that, all your other rights will soon be taken away. So, I may disagree with what you say, but I will defend until death, your right to say it! Last edited by sjaqua; 11-16-2004 at 02:13 PM. |

|

#6

|

|||

|

|||

|

Three or foure thing to remember when working a billet work the next process at welding temps never below you cant work it just hot needs to be realy hot it will take a while to learn this heat but that i think was your problem trying to work it to cold i dont know i was not there but every time i lose a bar is trying to go to far to soon

/when opening a bar its under lots---lots of stress even though it hot and moves fast or for to long it will shear open a bar with diffrent heats to get it pened --at the last weld -i have found that each weld needs three sets the first weld sticks it together the next set it deeper the third is to make the weld solid o ya the three most important things remember --HOT __HOT )_HOT ,and it will also help if the tong is in the right cheek __________________ Bowie Thunder Mountain Forge |

|

#7

|

|||

|

|||

|

Opening accordians can be tough. Best advice would be like Ron said, soak a long time at welding temp, I also flux and open slowly. Shears lenghtwise sometimes occur, so keep at it. Slow, hot, and flux.

__________________ Jason G Howell ABS Journeyman Smith howellknives@yahoo.com http://www.howellbladesmith.com |

|

#8

|

||||

|

||||

|

While it is certainly possible that my technigue at opening the accordian was at fault. I am more inclined to think it is the last set of welds that are at fault. Because only those welds failed. The welds that make up the laminted bars held up.

Now that is not to say I won't be taking extra care when I open up the next one. But rather to say that I will be working more on my welding technigue when welding the larger bars togather. __________________ Scott B. Jaqua http://www.hagersonforge.com http://hagerson.livejournal.com ---------------------------------------------------------------------------------------------- The most important right of all, is that of Free Speech. With out that, all your other rights will soon be taken away. So, I may disagree with what you say, but I will defend until death, your right to say it! |

|

| Tags |

| blade, forge, knife |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|