|

|

|||||||

| Register | All Photos | FAQ | Members List | Calendar | ShopStream (Radio/TV) | Search | Today's Posts | Mark Forums Read |

| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

hello new to the forum

Just wanted to say hello and appreciate the knowledge that is shared here. I am a newbie to knife making but not to tools. I like the emphasis on striving to do better. I have always had a desire to become great at something but without a good teacher I have always gotten bored and moved on to some other new interest. I am finding after only reading a few threads very good info. thanks and look forward to learning.

James |

|

#2

|

||||

|

||||

|

Welcome James! And, thank you for filling out your profile. That allows knife makers in your area to know they are close by so, eventually, someone will contact you (or you them) and you'll get first hand pointers.

No matter what, we're here. The best advice I can give you if you are about to make your first knife is to keep it simple. No matter your other experience, just make a small 4" knife and worry about getting the grinding and heat treatment right. Keep it simple because you need to make it quickly so that you can use it and, eventually, probably destroy it. Then make another one using what you learned from the last one. That's how you will learn if your heat treatment and your design resulted in a real knife or just something that looks like a knife .... |

|

#3

|

|||

|

|||

|

Thank you Ray , that is the good advice I had already gotten from your previous posts. I was glad to read that starting with O1 isn't a must. I don't have much money to invest and I will be using circular saw blades to start. So testing is a must. I haven't a clue what kind of steel it is. I was able to anneal it I believe. Its soft and any warp is easily straighten with a light tap from a hammer. I have a hole in my wall between my house and my shop so I frequently get inspired from other makers on the net and go work at all hours. I haven't finished a knife yet but I am getting there slowly but surely. thanks again for the welcome.

James |

|

#4

|

||||

|

||||

|

If "circular saw blade" means the kind of blade used on a Skil-Saw don't waste your time as the steel will not harden. Such blades usually have carbide teeth welded on to mild steel so they don't need to be high carbon steel.

If you mean an old saw mill blade then you might be all right as long as you don't find carbide teeth on it (for the same reason). Real blade steel is actually pretty cheap and then you'll know what you have. There is the shipping cost, of course, but if you can spare $20 you can get the whole thing covered and not have to guess .... |

|

#5

|

||||

|

||||

|

James,

Sound advice from brother Ray. Forget the small circle saw blades. Unknown steels are fun to play with, however, sometimes you might get lucky, but more than likely you are gonna lose in the long run. If I had to recommend a starter steel, it would probably be 1084. You can Google how to heat treat it and get many results. It is relatively a simple steel, but makes a great knife. Check with Aldo Bruno at http://njsteelbaron.com . He is a super nice guy and will sell you one stick to one truck load. His prices are very reasonable. I would hate to see you get discouraged right off by using some garbage to make your first blade. Get a known steel and do a little research on how to handle it. You won't be disappointed. They only get better after the first. Good luck............. Robert Dark |

|

#6

|

|||

|

|||

|

Let me echo what Ray and James said. If you can't afford to get a known steel then you can't afford the time and money spent to finish a knife with a blade that will never hold an edge. Aldo is real good people and a knowledgable knifesmith. Admiral steel doesn't charge much for a 6 fool length of 1075/1080, and Kelly Cupples, reached through Hight Temperatur Tools and Refractory, is another good source. Some times free steel can get expensive.

Doug __________________ If you're not making mistakes then you're not trying hard enough |

|

#7

|

|||

|

|||

|

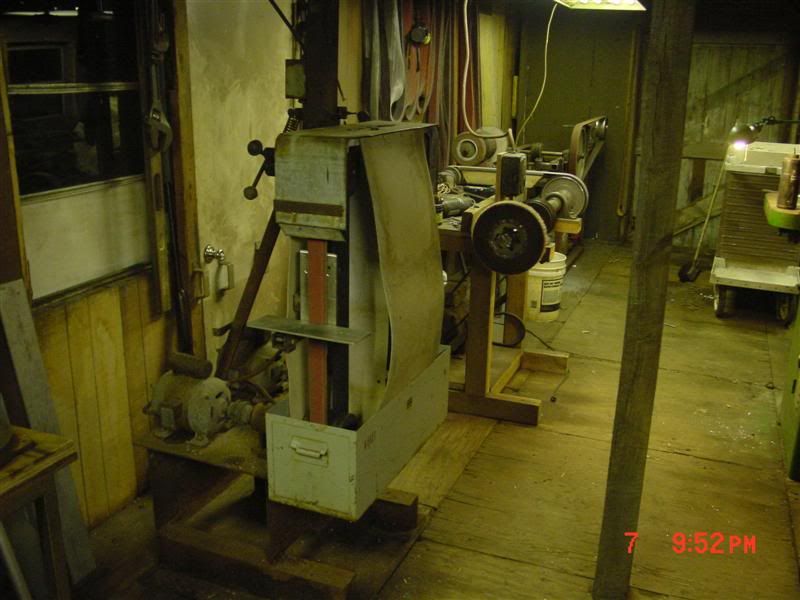

Thanks for the heads up. I have read that before. It is the type with carbide teeth although I do have several 40+ inch circular saws from sawmills. The one I have used is about 20 inch diameter. I will have to try and HT sooner than later. Time is less valuable to me than money. What I mean is. I have a lot more time than money. I am using a wet grinder to grind and it does seem to give the belt a lot of life so no waste there really . I made this jig last night . I got the idea from this forum and member Frank Niro. It worked great. This is my first attempt at flat grinding. I don't have a HT furnace yet but I will try and just torch a piece up to NON magnetic and quick quench to see if I can get it hard. It may not be a quality steel but it was still fun to try. Well I just tried to HT. before a file would cut it. Now it skates off. I know I would need to temper but is this a good first sign? [IMG]

|

|

#8

|

||||

|

||||

|

James,

Welcome to the forum! By the way that looks pretty good for a first attempt at a flat grind, if you ask me. Jeff |

|

#9

|

||||

|

||||

|

Welcome to the forum, James. Looks like you are off to a good start. I like the idea of the wet grinder. I have thought of doing this with my regular grinder, but obviously someone has already thought of it. I'll have to look into this...

__________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#10

|

|||

|

|||

|

thanks Jeff and ckluftinger . I know I have a long way like the rest of my life to get better.

the wet grinder I bought for 150 at a glass shop I work at a few times a month when they need my help. Its from 1950 and was a double belt machine. It took 2 4 x 106 belts. I found that it would accept a 132 belt but it didn't give me the ability to use both sides and also I wasn't looking to buy any more belts. I dropped both tensioned idler wheels down so I could use a 72 inch belts . I had to add a few splash guards but really it contains the water very well.

|

|

#11

|

|||

|

|||

|

Thanks. I posted a couple pics of the grinder. If the moderator approves them you will see its a pretty simple setup. The idea is really is just to keep the belt moist and not wet wet. The water on mine which is vertical is applied at the bottom of the operators side. It allows excess to be flung off by the time it gets to the work. I modified the machine to work with 72 inch belts which was a simple as tapping a half dozen new bolt holes to drop the Top. I would recommend to anyone who can pickup a glass grinder to do so an not let belt size worry you. I think modifying any belt grinder run wet is just about containing the spray and also having the proper electrical setup. If it doesn't get wet it shouldn't be an issue.

One other thing. I realize this is just a flat vertical setup but I have seen people use platens that are curved and think in the future I may experiment with that. Good luck and thanks again. James |

|

#12

|

||||

|

||||

|

You learn something new every day... Thanks for sharing this info, James!

__________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#13

|

||||

|

||||

|

To answer your question, James, yes, if the file skates off the steel then the blade did get hard (assuming you used a fresh, sharp file). That doesn't mean it is great knife steel just yet but it is worth continuing with this blade to find out ....

|

|

#14

|

|||

|

|||

|

Thanks Ray , I have so much to learn . I think I have found a home here.

ckluftinger I am glad to share. James |

|

| Tags |

| art, blade, forge, grinding, guards, hammer, handle, heat treat, jig, knife, knife making, newbie |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| What's sub forum is right? | U.C.O.K | Factory Knife & Mid-Tech Discussion | 0 | 06-28-2008 01:46 AM |

| New Here on the Forum | Foxjaw | The Outpost | 7 | 08-21-2007 09:14 AM |

| Something different for this forum. | Terrill Hoffman | Knife Photography Discussion | 3 | 07-25-2006 03:02 PM |

| New Forum | dogman | Knife Making Discussions | 22 | 08-30-2005 04:11 AM |

| A new forum | AbelKnives | Knife Making Discussions | 0 | 02-16-2002 07:51 PM |