|

|

|||||||

| Fit & Finish Fit and Finish = the difference in "good art" and "fine art." Join in, as we discuss the fine art of finish and embellishment. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

The grind line from the ricasso to the edge.

Being relatively new here, I wonder if the subject of this edge transition has been discussed here. If not, I'd like to offer an opinion.

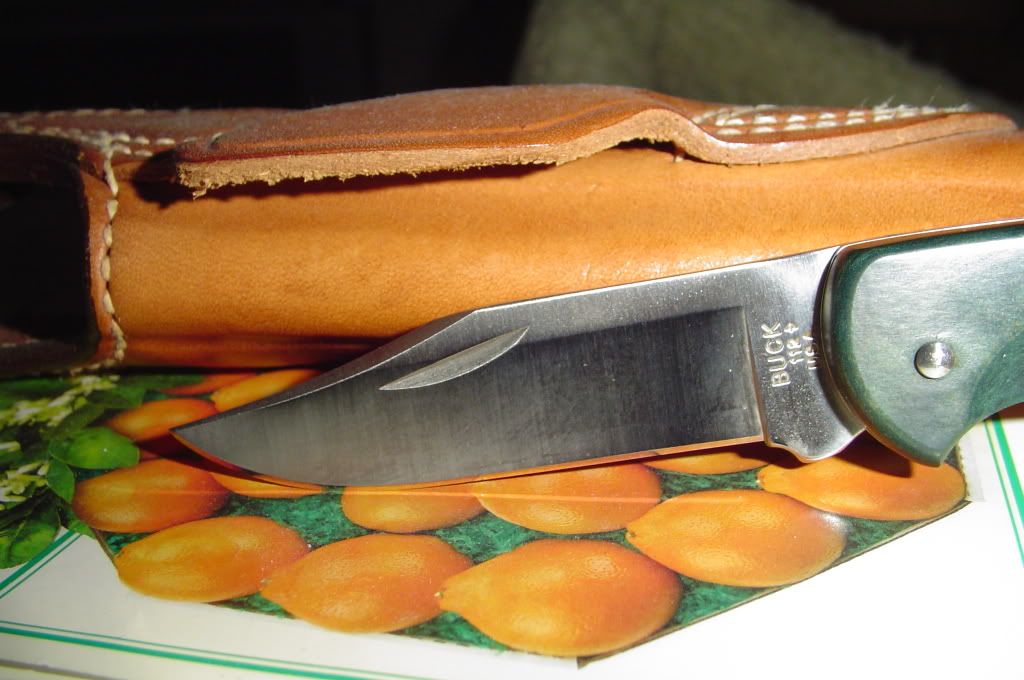

Overall, my job as a 'tinker' is to fix, repair and polish the edges of EDC pocketknives and kitchen utensils. While many knives are created for their beauty, my focus is on edged tools that work for a living. One such issue is the 'fillet' or the rounded out portion of the edge gently blending the blade blank from the ricasso to the edge. Not all of my clients return for service each and every time an edge goes dull. Knowing that, I try to give them a fighting chance to service their own edge, and perhaps help me refine the edge a few times per year. I can best help the client by removing this transition by carefully chasing out the fillet, and making the edge a square fit to the ricasso. This makes it easier for the client or myself to more perfectly engage the edge to the stone during subsequent polishings. The cutler can also provide a choil directly in front of the ricasso. This is a fantastic aid in sharpening a knife intended to be an EDC. Below are two examples. The first is an Emerson Snubby that came with such a choil. It was easy to polish out the edge. The second picture shows the refining of the edge to square it up. You might not want this done on a knife designed to be a collectible, but it helps in daily use.

|

|

#2

|

||||

|

||||

|

I have the same line of thinking as you do when I make my knives. I'll usually add a notch (or a choil as you refer to it) right at the edge of the ricasso to keep it from interfering or getting marred up while sharpening.

__________________ -Andrew Riley For the word of God is living and active and sharper than any two-edged sword.... (Hebrews 4:12) My YouTube Channel: www.YouTube.com/ARCustomKnives Check it out and Subscribe! |

|

#3

|

|||

|

|||

|

Thank you for your response. I'd like to see your bevels and to see how you solved the problem.

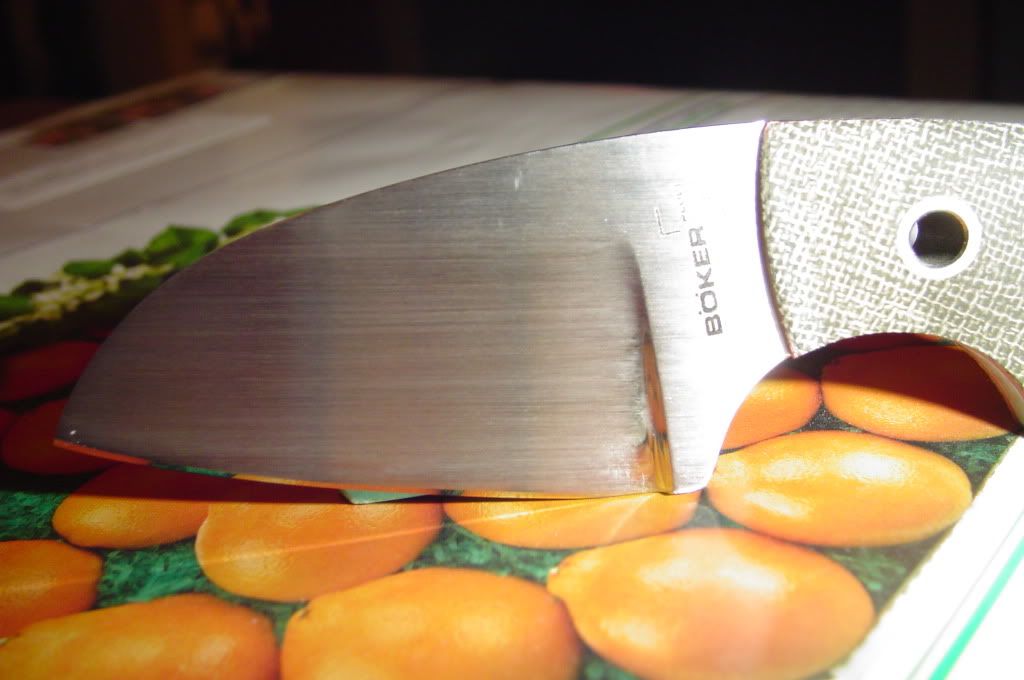

I did want to add another comment. This applies more to kitchen knives where the bolster starts as being level with the edge when the knife is new. Over time, the edge is slowly "nibbled" up and the bolster hits the cutting board first when the knife is used for heel cutting. Below is an example. This is a small Boker knife called a Gnome. There was so much metal on this bolster that grinding it off would have wasted metal and ruined the appearance. I chose to blend the edge into the bolster.

|

|

#4

|

||||

|

||||

|

I agree, choils are the way to go. I used to make a few without them but now, they all have them or the ground edge extends all the way to the ricasso like on a guarded through-tang knife.

__________________ Dennis "..good judgement comes from experience, experience comes from poor judgement.." -Gary McMahan, a cowboy poet and good dancer. http://www.facebook.com/home.php#!/p...24112090995576 |

|

#5

|

|||

|

|||

|

Quote:

I must stress that my comments deal with knives that are to be used on a regular basis, and need to be sharpened or repaired. Clearly, a knife made for a show, or to demonstrate the cutler's skill might never be used and the issue I raised does not apply. I must admit I have slowly 'raised the bar' on my opinion of use and abuse. The first good knife I owned cost 90 bucks. I found myself constantly running my palm down the edge of my right pocket to feel for the clip, and worried the knife had bounced out. Of course, then I bought a 200 dollar folder... My Dad brought up a good point. He moved us to an upwardly mobile subdivision in the mid-1950s. That home cost 28K. He told me that story as I was sitting on a 30K custom Harley. I now have many "love marks" on my EDC ZT0300! My point is this. If a knife design is formed by the cutler for a client and they both feel that a choil detracts from the appearance, then that is another issue. But if a client approaches me and stresses continual use and needs the best design for his personal use that is another matter all together. And this happens. I have one client who likes Sambar stag grips and damascus blades, and he uses them daily. That's what he wants. We had this same discussion years ago, and he chooses better designs for his lifestyle. |

|

#6

|

|||

|

|||

|

Choils are just hang ups !!! Have you ever used a knife with a choil for work on a downd animal ? You will be sorry you ever placed it there. On knives used elsewhere it just proves to be a nicker. Tips of knives are used with care but when it comes to cutting it's the area near the handle that is put into use. Certainly sharpening has it's own problems, but adding choils while they may look good and make sharpening easier , just produce another problem. Frank

__________________ Without collectors there would not be makers. |

|

#7

|

|||

|

|||

|

As a matter of fact, I got this idea from owning many Graham Brothers knives, both the SS3 and the Stubby. Both have choils, and many of the Graham clients use these knives for hunting, in fact, pig hunting. Wisconsin is a big whitetail deer hunting state.

My two personal Grahams are the second and third one in the picture below. Now, my singular personal experience means virtually nothing statistically. But my anecdotal experience regarding folders is 43 years on the back of a Harley. During that time I have been exposed to loading dock soot, torrential rain storms, crappy food, workplace abuse, and my own youthful ignorance about knives. Just buying a cold beverage subjected my knives to the proverbial "blood and the guts and the beer." These four decades actually produced more damage to knives from sloppy sharpening practices than the muck caught in choils. And that included two trips to South Dakota. I will grant you this, on kitchen knives it's better to have the blade made with no bolster "heel" at all. In other words, the edge runs clear back to under the ricasso, and is never technically part of it. You do have to 'break' the back part of the blank to keep the chef from running his knuckles on to that sharpened rear angle.

|

|

#8

|

|||

|

|||

|

Hey, where are you going? We were talking about choils and now you are on your knife use in bike riding and going to South Dakota ? My experience in choils is from the hunting thing. I'm not talking about use on one or two animals I'm talking about hundreds, several of which were mine. I started out with placing choils to make sharpening easier but soon heard about the problems they created. Do you think the factory makers leave lthem out because they are such a problem to install? They create problems and don't solve them. Frank

__________________ Without collectors there would not be makers. |

|

#9

|

|||

|

|||

|

I was trying to demonstrate that choils have had no, zero, zip, zilch, nada effect on any knife design I have carried, sharpened, used, and abused at any time in my life in forty years as a consumer.

However, sloppy grinding transitions from the bolster or the ricasso onto the edge have caused nothing but problems for both myself and my clients. Clear and simple? |

|

#10

|

|||

|

|||

|

The point is that in some applications a choil does cause problems, even if you personally have not had any. Frank is not the only one who has had problems and he is a knowledgable knife maker. Ed Fowler, who is a master knifesmith, rancher, and writer, also feels the same way about choils. There are many people on this site that have a lot of experience in making and using knives. Probably more than you. You might want to consider that when you reply to a post you have differences with.

Doug Lester __________________ If you're not making mistakes then you're not trying hard enough |

|

#11

|

||||

|

||||

|

Quote:

The majority of customers that I have known in nearly 30 years of doing this around the world disagree and want nothing to do with it, like Frank mentions in his post, they are a hangup and do not want them. Now you're talking about factory knives, totally different world from Custom. I tell most of the people I sharpen factory knives for to tape a $.25 to it and throw it in the trash, that way they can say they threw something of value away, then take a few $'s and buy themselves a good knife. John I. Messermacher __________________ Life Member: NRA, VFW, & The Alaska Bowhunters Assn Voting Member: GA Custom Knifemakers' Guild and The Knifemakers GUILD MSG, US ARMY Retired |

|

| Tags |

| blade, custom, damascus, folder, hunting, knife, knives, palm, post, sharpening, stone, tang |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Sanding the grind line? | Jim T | The Newbies Arena | 10 | 05-03-2010 08:40 AM |

| what's happening here (grind line) | Txcwboy | The Newbies Arena | 12 | 03-16-2008 11:01 AM |

| raising the grind line | Txcwboy | The Newbies Arena | 6 | 01-08-2008 08:59 PM |

| How to get distinct ricasso/edge transition? | Mike Routen | Ed Caffrey's Workshop | 11 | 10-10-2004 05:43 PM |

| Grind Line question | Tamahagane | The Newbies Arena | 3 | 01-23-2004 09:34 AM |