| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

12-02-2012, 08:25 AM

|

|

Enthusiast

|

|

Join Date: Oct 2012

Location: Mass

Posts: 42

|

|

|

Quote:

Originally Posted by Crex

Like NJS says, still got to keep an eye on it.

My forges are fired with Lp and I can melt steel in them. I do forge welding in two of them using venturi (not blown) torches. Lot of "experts" say you can't do that....it's a design application thing. Not hard to accomplish at all.

Friend of mine used to make and use 2-brick forges fired with a simple handheld Lp torch and I had to show him how to regulate his forge so he didn't burn up his steel. Got way too hot. Just keep an eye on the heats and catch non-magnetic on the rise not the fall in temperature.

|

Thanks, will watch the non magnetic carefully.

|

12-09-2012, 05:36 PM

|

|

Enthusiast

|

|

Join Date: Oct 2012

Location: Mass

Posts: 42

|

|

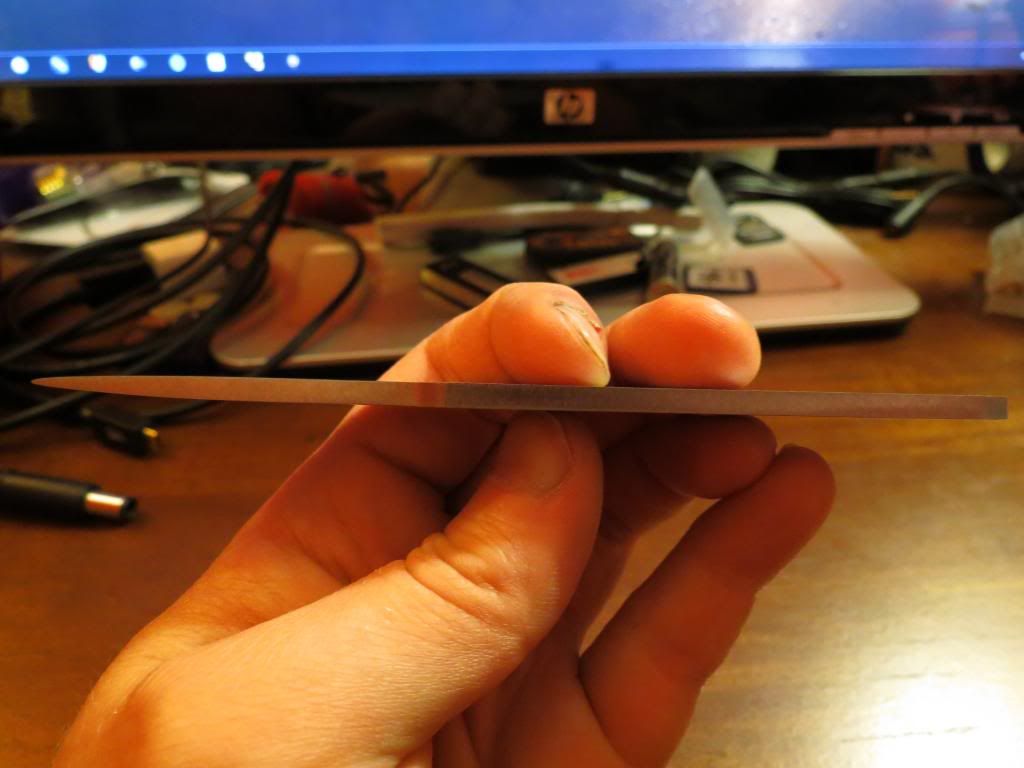

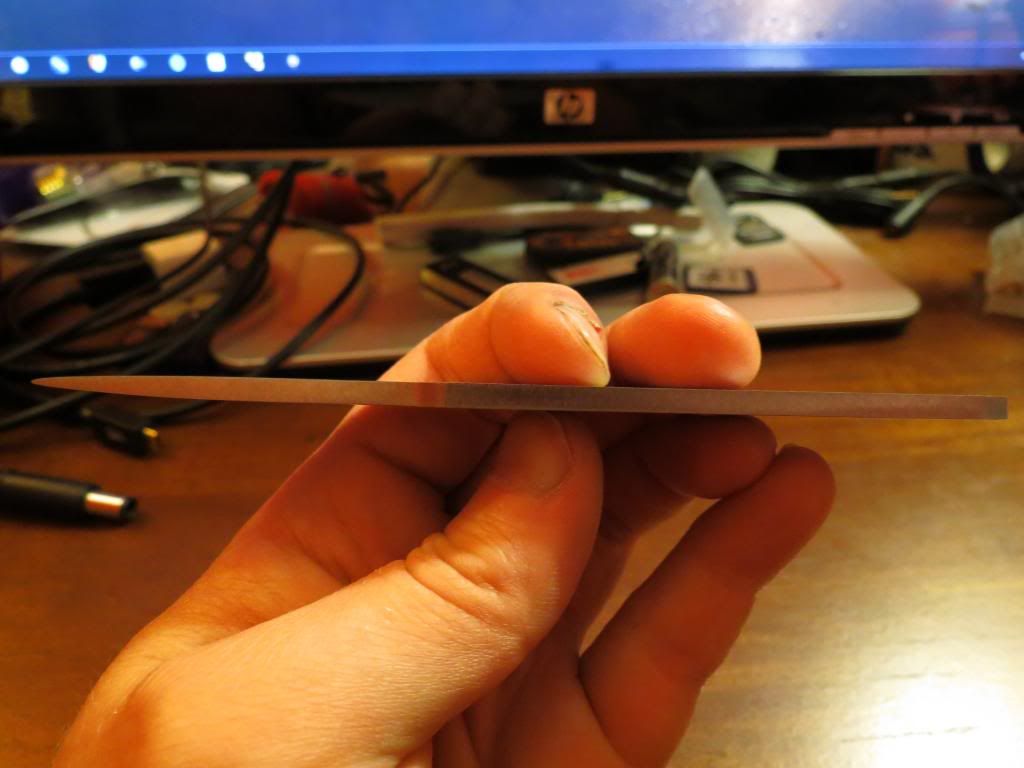

ok, here is take #3 of the same design, #2 was only slightly better than #1, very crooked.

This one is fairly straight, is there some trick to the ricasso? It still eludes me how to get it straight and where I want it.

Also I believe I left the edge too thin again before heat treat. I need to construct my forge next and then I can play with the putting on an edge.

|

12-10-2012, 07:06 AM

|

|

Steel Addict

|

|

Join Date: Oct 2012

Location: Rush, KY

Posts: 238

|

|

|

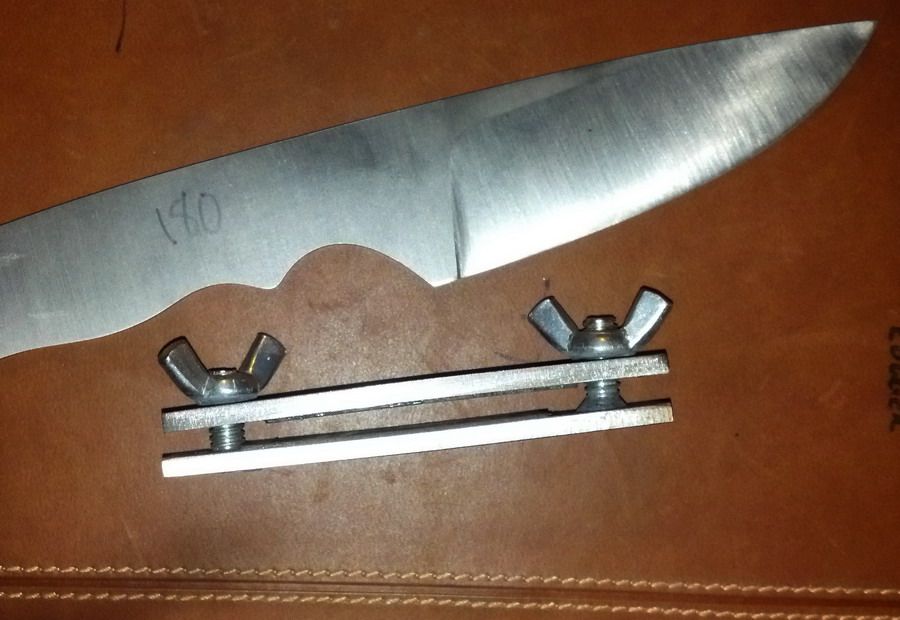

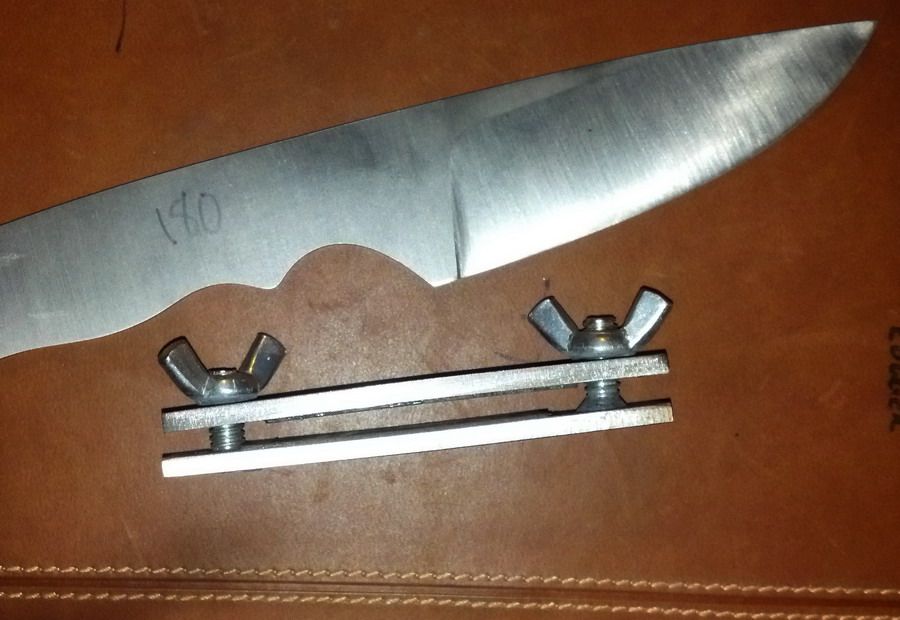

A lot of people use a file guide to keep their plunge cuts neat. They are a little pricey though. I use a steel parallel clamp like machinists use. It isn't as good, but the good ones are hardened and it works alright if you can cope with the bulk.

|

12-10-2012, 07:32 AM

|

|

Skilled

|

|

Join Date: Jun 2012

Location: Winter Park, CO

Posts: 366

|

|

Regarding equal plunge lines for the primary bevels....

I fabricated a file guide from leftover ATS-34 billet (1/8" thick) for next to nothing. I haven't gotten the guide heat-treated but I only work with hand files so wear hasn't been an issue yet.

It works well.

__________________

Stay away from fast women and slow horses

|

12-10-2012, 05:23 PM

|

|

Enthusiast

|

|

Join Date: Nov 2012

Location: Norman, OK

Posts: 35

|

|

|

Looks good. I made one out of some 1/4" thick hard stainless steel I found at work.

|

12-10-2012, 06:21 PM

|

|

Founding Member / Moderator

|

|

Join Date: Jun 2002

Location: Wauconda, WA

Posts: 9,840

|

|

|

I made the same thing from hardened O1. You can make them from any steel you can heat treat. Just do the drilling and tapping, then harden the steel but don't temper it at all. Pretty darned tough that way ...

|

12-10-2012, 08:09 PM

|

|

Hall of Famer

|

|

Join Date: Sep 2005

Location: Central Ohio

Posts: 2,193

|

|

|

You can also use a round file (like used for sharpening chain-saw blades) to cut in the "plunge" before grinding or filing in your bevels. That gives you a small safety zone to watch so that your grind doesn't wander and wash out.

|

01-21-2013, 02:09 PM

|

|

Enthusiast

|

|

Join Date: Oct 2012

Location: Mass

Posts: 42

|

|

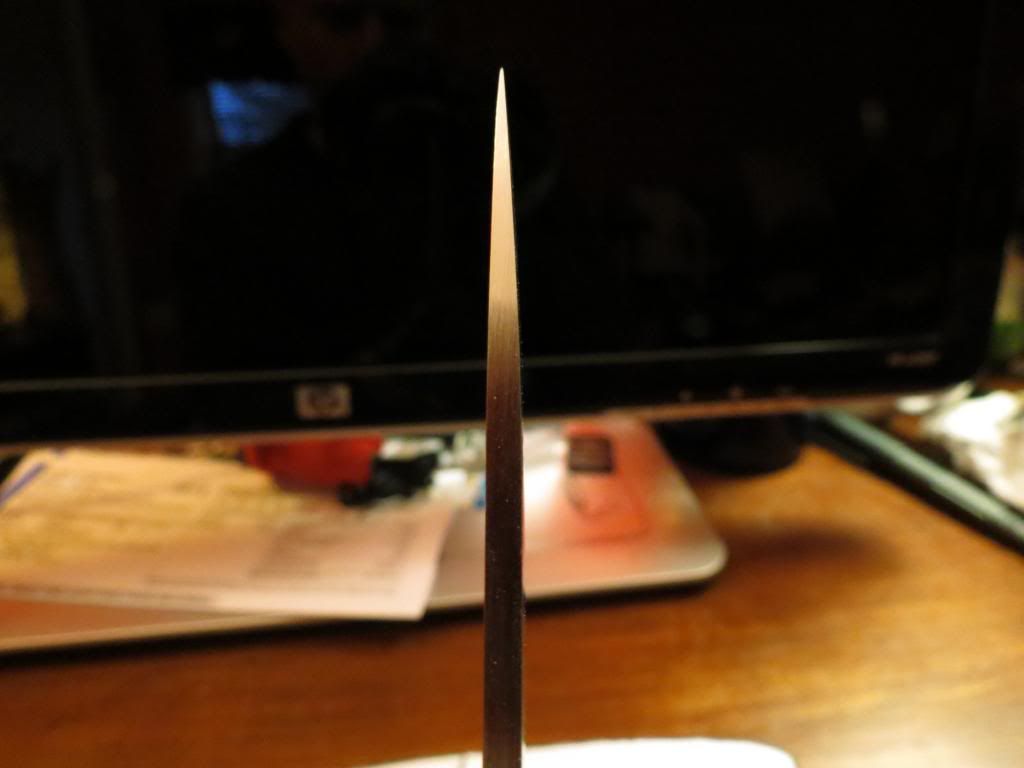

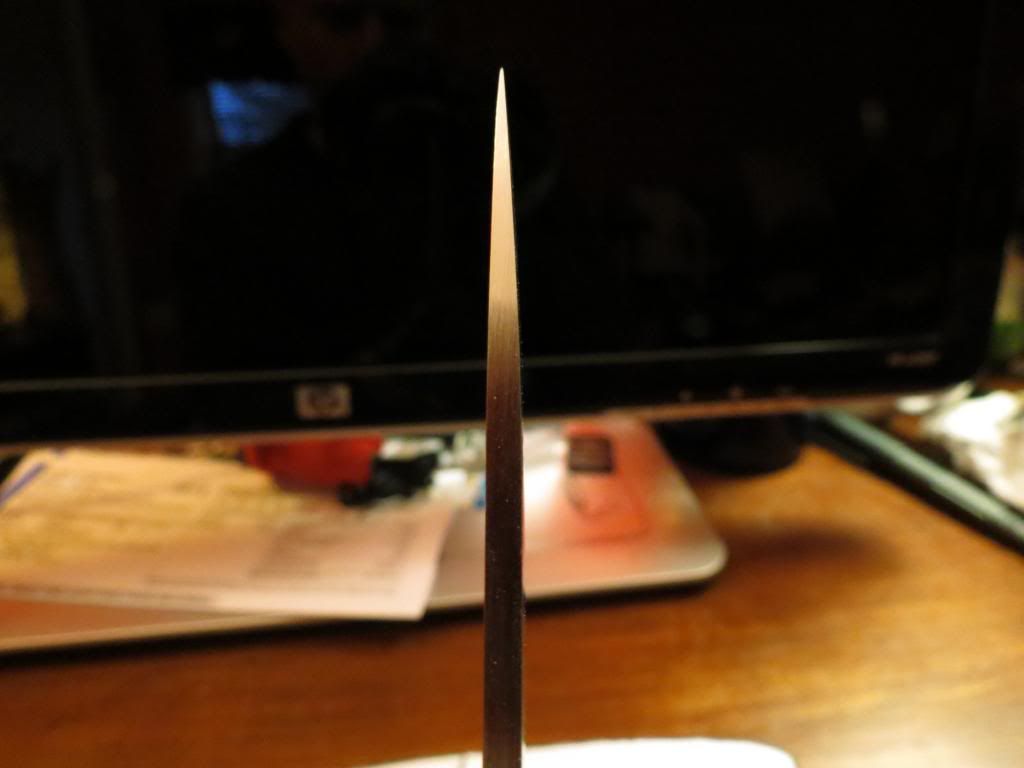

This is my 4th grind and a new design. This one is actually looking decent.

I am guessing I should take the edge down to something a bit thinner, it goes from .86 - .5 (tip)? I've seen recommended .20 before heat treat? I'll be heating treating it myself, got to construct my forge, parts sitting on the bench.

Then once heat treated, how far down do you grind before putting the edge on?

Thanks

|

01-21-2013, 05:05 PM

|

|

Enthusiast

|

|

Join Date: Oct 2012

Location: Tasmania, Australia

Posts: 81

|

|

|

I can see a definate improvement in your skills. Nice looking blade!

__________________

R Rogers Knives

|

|

Tags

|

advice, back, beginning, blade, build, building, design, easy, edge, flat, forge, grinding, handle, heat treat, hot, how to, knife, knives, made, man, material, plastic, simple, steel, wrap  |

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -5. The time now is 05:07 AM.

|

Similar Threads

Similar Threads