Hello everyone !!

I have been making knives for approximately 18 months and produced 28 knives all on my

20 yr old Sears 1x30" 1/3hp sander. Like most new knife makers, we are on a VERY limited budget

and not all of us can afford that awesome KMG 2x72. For the last 4 months, I have been researching

on how to make my own 2x72. Watched many videos and read more forums that I care to

admit to. In many cases, I have seen these made from treadmills. Has everything you need;

bigger motor, bearings, variable speed, etc.

I have talked to many sources lately and have warned me about using a treadmill setup for my

2x72. The motors, bearings, and belts are all different. I was also told that since it was an

open motor, shaving and debris would ruin the motor quickly. OK, I believe all of that.

But because of all the research that I have done on this treadmill setup, I decided until I could

afford to build that 2x72, that I would soup up my 1x30 and make a variable speed unit so I

could slow everything down from my normal 3450rpms. (a finger and steel burning maching)

Everything I found and read was strictly about the 72 and not many modifications about 1x30.

Here is a WIP that I did to hopefully help the new makers out there, on a budget, make something

until they can move up to the bigger machines.

Here is my current setup that I have been using for all my knife making including handles:

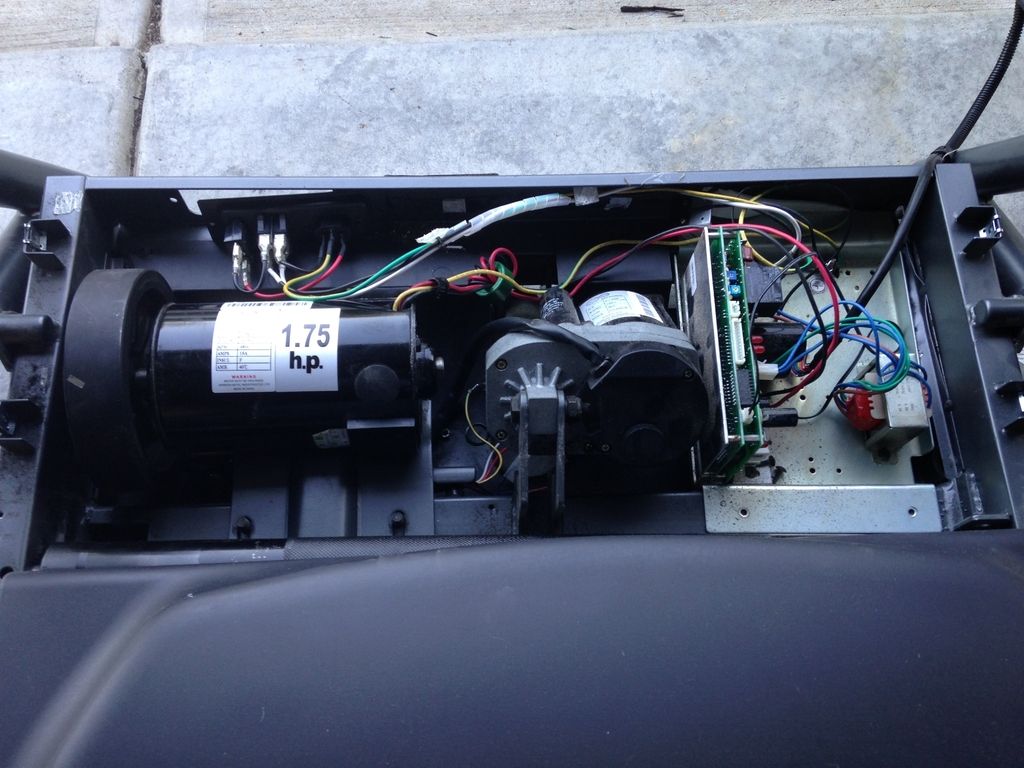

I then went to craigslist and watch it for about a month looking for the best deal and the

biggest motor. This guy just wanted it out of his garage. He wanted $125 for a month and

no takers. I called him up and offered him $30 to haul it away. He accepted.

[IMG]

[/IMG]

[IMG]

[/IMG]

Next thing I had to do is undo the tracking and pull out the long bearing units that the mat

ran on. Found out that the pulley system was totally different than I expected. Wasn't a flat

belt or a V. Opps... now what...hmmm. I tried to disassemble the bearing unit to get the pulley

off but somehow it was fixed to the long bearing bar. I waited awhile and disassembled the 1x30:

[IMG]

[/IMG]

I wasn't able to get the bearing unit off so I decided just how to get the pulley assemble off.

I was locked into the bearing and epoxied in. After some choice words, I was able to get it off.

It just left me with an 8 thread round rubber piece with a 2.5" hole in it. How was I going to

but that on a 13/32" shaft. I came up with this. I made a wood circle to act like the bearing

unit. I also added 2 pieces of aluminum rods into both to make sure that neither would spin

under pressure. All of it was epoxied together.

[IMG]

[/IMG]

After cleaning all that up and making sure it was true, I attached it to my grinder. I then pulled

the motor out and the control boards to see how I would line everything back up.

[IMG]

[/IMG]